Robotic Assisted Knee Replacement

- Adapting Social

- Dec 15, 2020

- 1 min read

Updated: Feb 23, 2021

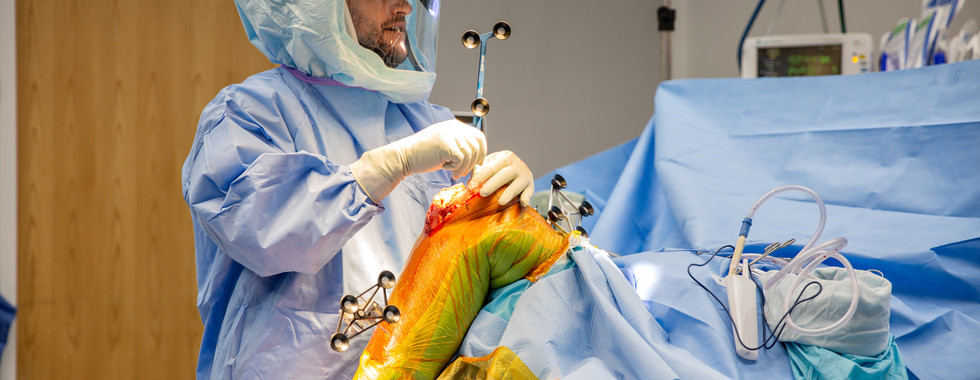

What is robotic assisted knee replacement?

Robotic technology has advanced tremendously in many industries like aerospace, pharmaceuticals and manufacturing. Computer navigation and robotic arm technology allows for more precise and reliable implant sizing, positioning and balance of the knee joint. This has the potential for improved patient outcomes and implant longevity.

How is Robotic assisted knee replacement done?

Prior to your surgery a 3D model of your knee joint is made using computer software. Your surgeon then plans your surgery prior to ever entering the operating room. Smaller incisions with less tissue damage can be done since less exposure of the knee is required. The implant size, position bone cuts are optimized to match the patients specific anatomy and deformity. During surgery the surgeon exposes the knee joint in the same way as a traditional knee replacement. The knee is then taken through a range of motion and fine adjustments are made to the implant position to achieve a balanced knee within 1mm of accuracy. The surgeon then operates the robotic arm which executes the bone cuts within 5mm of precision. More precise cuts allow for the use of cementless, press fit implants. The use of the robotic arm allows for a more balanced knee and the use of implants that are press fit as opposed to cemented like traditional implants. This has the potential for improved patient outcomes and increased implant longevity.

Advantages of robotic assisted knee replacement

More precise implant positioning

Personalized implant sizing to match patients anatomy

Increased utilization of cementless implants

Improved knee balancing

Improved implant longevity

Smaller incision and less soft tissue trauma

Comments